3D rendering is essential for manufacturing companies. It allows people to see their ideas in three dimensions, which can help them to make better decisions about their projects.

This software can save the company time and money in the manufacturing industry and help them to avoid costly mistakes.

If you are a business owner interested in the future of manufacturing, this article will cover why your manufacturing company should consider 3D rendering!

What is 3D Rendering?

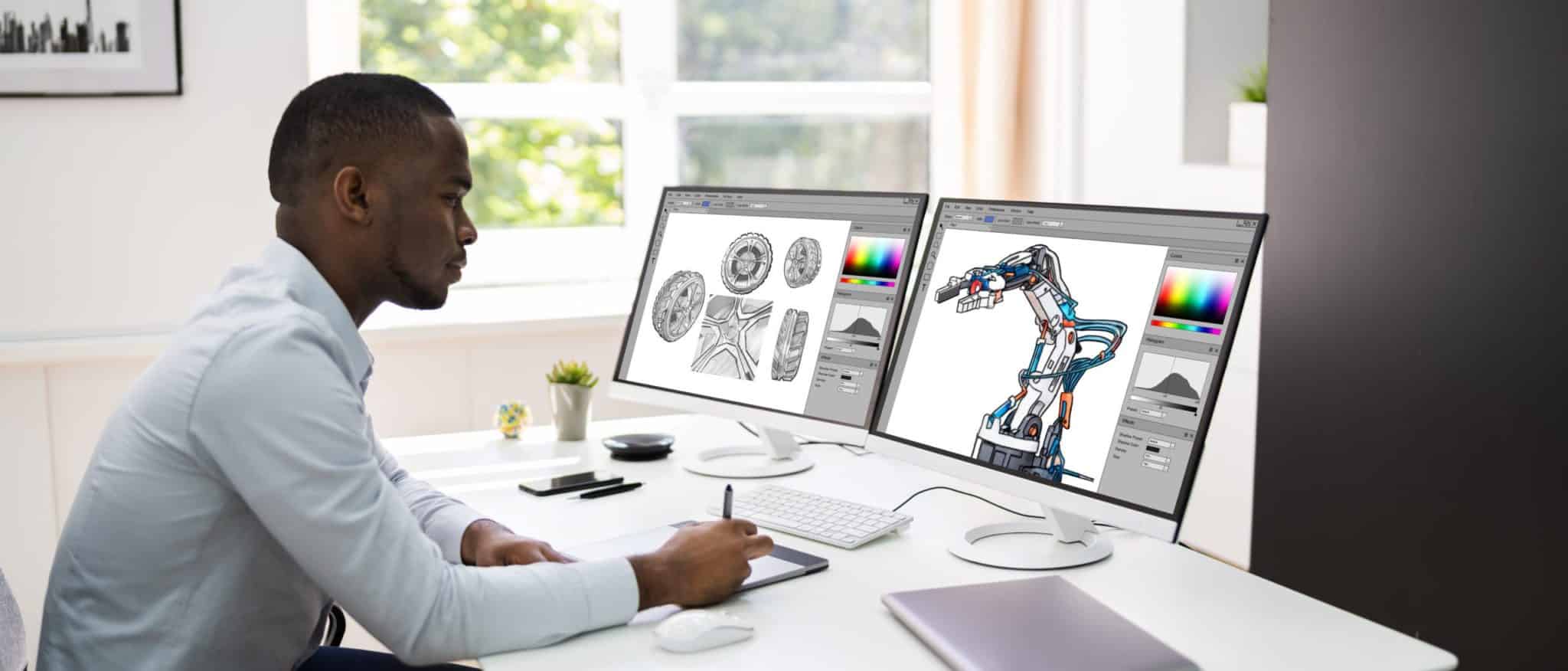

3D rendering has revolutionized the manufacturing industry. This technology allows users to create realistic three-dimensional images from a two-dimensional drawing or model with just a few clicks of a computer mouse. It can be used to create a realistic image of a product or scene or a more abstract image.

3D rendering is often used in advertising and product design, and it is also used in video games and movies. This technology is constantly evolving, and new applications are being constantly discovered.

3D rendering can be used for a variety of purposes, such as:

- Product Prototypes

- Marketing Materials

- Video Game Graphics

- Film Graphics

However, it is also used in the prototype manufacturing process to create new products or images of products about to go into production.

Additionally, 3D rendering is used to create images of entire factories. This can help manufacturers plan out their production lines and identify potential problems.

So, Why Is 3D Rendering the Future of Manufacturing?

3D rendering is another technology that is quickly gaining popularity in manufacturing. It allows companies to create digital prototypes of their products, which can be used for testing or marketing purposes.

It is a powerful tool that is changing the manufacturing landscape, and its popularity will only continue to grow in the future. Its speed and efficiency make it the perfect tool for businesses of all sizes to create high-quality products quickly, and its ability to create realistic graphics makes it a must-have for video game developers.

A digital prototype can give customers a better idea of what the final product will look like and can also help generate interest in the product. Additionally, 3D rendering can be used to create animations that demonstrate how a product works or how it works.

There are many reasons why 3D rendering is the future of manufacturing, including the following:

- You can create high-quality prototypes

- It can help save on costs

- You can use 3D rendering for marketing

- The design process is faster & more streamlined

- 3Drendering allows more team collaboration

- 3D rendering is more sustainable

- With 3D rendering, you can quickly fix mistakes

Let’s explore each of these reasons in more detail!

You can Create High-Quality Prototypes

3D rendering is the future of manufacturing because it allows manufacturers to create digital prototypes of their products. This means they can test different designs and see how they would look and function before creating a prototype.

This process also allows manufacturers to be more innovative since they can experiment with different designs and see which ones work best. 3D rendering is also beneficial because it allows companies to create models of their products that can be used for marketing purposes.

It can Help Save on Costs

3D rendering can save on costs by helping to create prototypes and models for products. This can help to speed up the manufacturing process, as well as help to ensure that products are of the highest quality before they are released to consumers.

3D rendering can also reduce the number of prototypes created, saving manufacturing costs. Additionally, 3D product rendering can help companies visualize how a product will look once it is completed, which can help avoid costly mistakes.

You can Use 3D Rendering for Marketing

3D rendering can be extremely beneficial for businesses when it comes to marketing. When potential customers see a product in 3D, they can better understand what it will look like and how it will function. This can be especially helpful for products not yet available to the public or still in the prototype phase.

3D rendering can also create images and videos showing how a product can be used in everyday life. This can be a great way to attract attention to a new product and generate consumer interest.

Finally, 3D rendering can create marketing materials such as banners, posters, and websites. By using 3D renderings, businesses can create attractive and eye-catching marketing materials that will catch potential customers’ attention.

The Design Process is Faster & More Streamlined

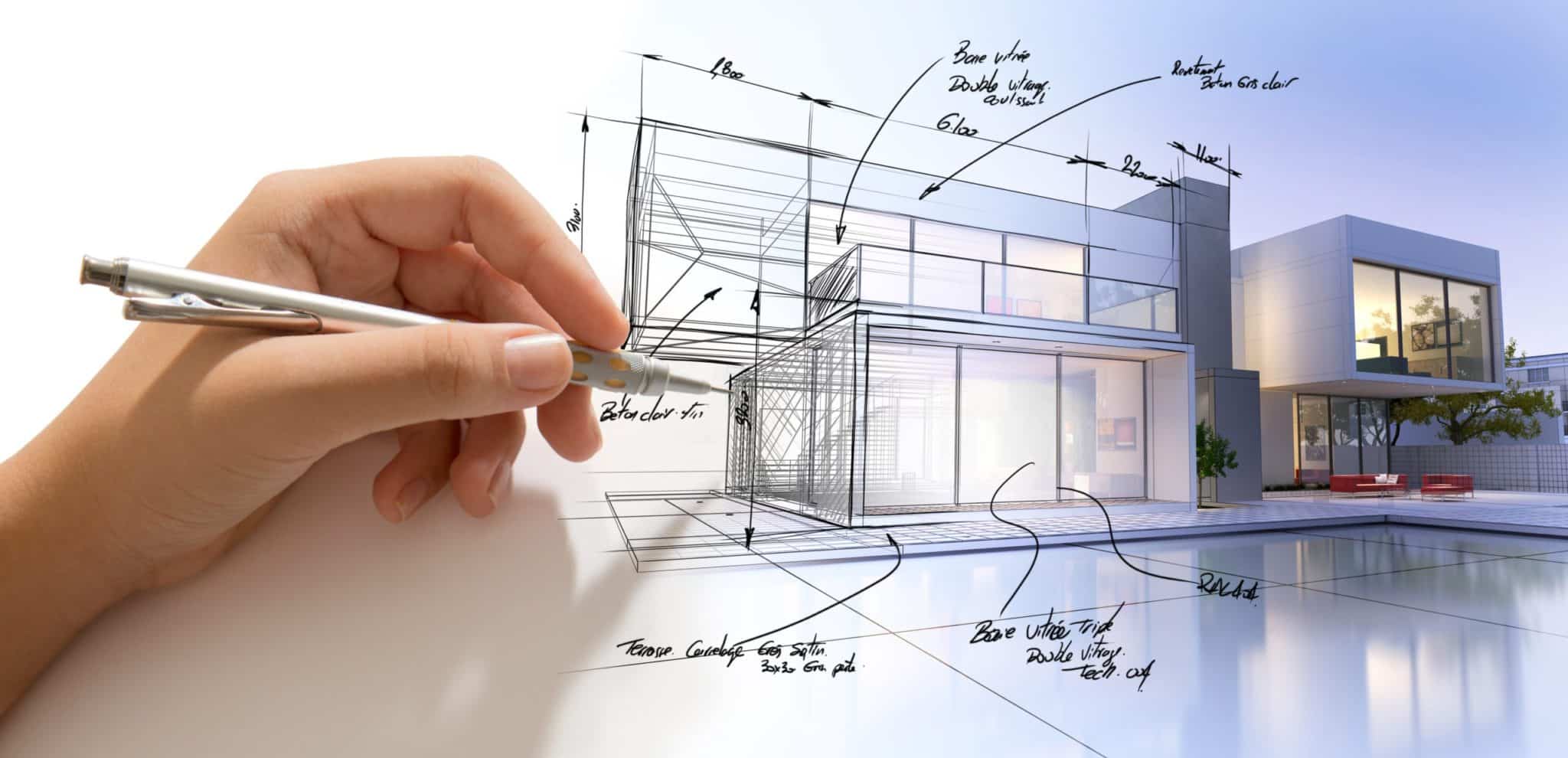

The 3D rendering design process is faster and more streamlined than traditional manufacturing methods. What makes 3D rendering so useful is that it is very fast and efficient, whereas the traditional manufacturing process is slow and often results in low-quality products.

The initial design phase can be completed quickly, and changes can be made easily. This makes 3D rendering an ideal tool for businesses that need to create prototypes or marketing materials quickly and on a budget.

3D rendering is also becoming increasingly popular with video game developers. The level of detail achieved with 3D rendering allows for realistic graphics that look right out of the movie theater.

3D Rendering Allows More Team Collaboration

3D rendering offers a much higher level of collaboration between teams. With traditional manufacturing methods, getting everyone on the same page can be difficult. Different teams might work on different product parts, leading to inconsistencies and errors.

However, this software allows all team members to work on the same product and see the same results. This makes it easier for them to communicate and collaborate effectively.

It also helps to ensure that the final product is consistent and accurate. Investing in new technology makes it easier for business owners to manage a manufacturing business and stay competitive in the market.

3D Rendering is More Sustainable

3D rendering is becoming increasingly popular in manufacturing due to its sustainability benefits. It uses less energy and does not require any physical materials to generate, which creates far less waste than traditional manufacturing methods.

This makes 3D rendering a more environmentally friendly option, which is important for the future of manufacturing. 3D rendering also allows for greater flexibility and customization in the manufacturing process, which can help reduce waste overall.

With 3D Rendering, You can Quickly Fix Mistakes

3D rendering can quickly fix mistakes by allowing changes to be made to the design without needing to start from scratch. This can also save time and money and ensure that products are of the highest quality.

Additionally, 3D rendering can help businesses prototype new designs, helping them test whether a product will be successful before it is even manufactured. This can help avoid costly mistakes and ensure that products appeal to consumers.

3D Rendering Wrap Up

The benefits of 3D rendering are clear, and it’s quickly becoming the standard for manufacturing. With its ability to improve quality, speed up production, and reduce costs, it’s no wonder that so many businesses are making the switch. The future of manufacturing is in 3D rendering, poised to change how we produce goods forever.

Are you a business owner interested in 3D rendering? Do you have any questions about how 3D rendering impacts the manufacturing industry? Let us know in the comments below!